70-D3B-2 LS Two Thread, Locked Stitch Butt Seaming Machine

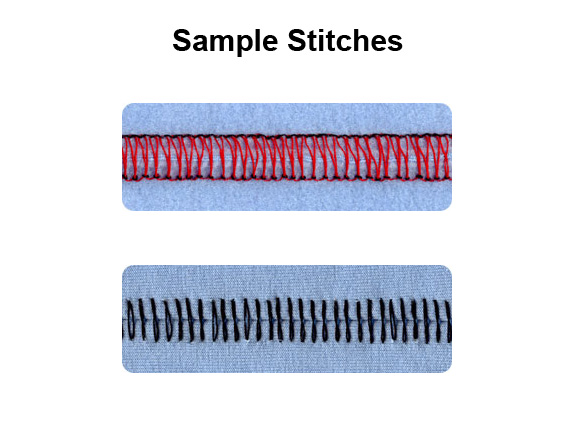

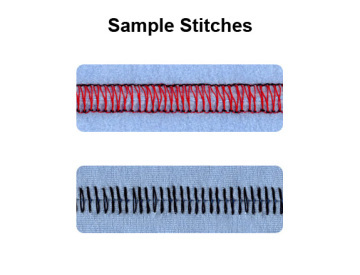

The 70-D3B-2 KS==LS is a two thread machine where the second thread locks the stitch in place. The "Locked Stitch" machine is used for seams that require added security or for fabrics that will undergo a napping process.

The Advantage of the 70-D3B-2 LS

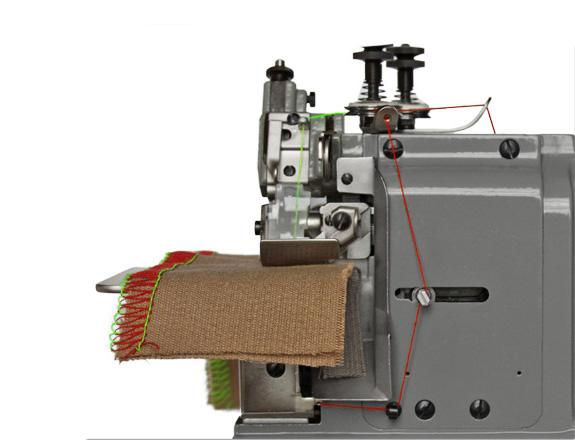

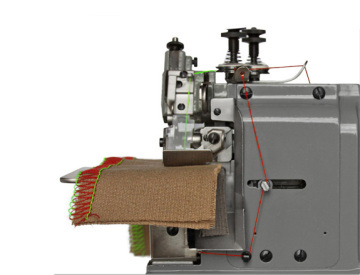

The Merrow 70-D3B-2 LS industrial sewing machine creates a two-thread butted seam on woven and non-woven goods. The second thread acts as a 'locked-stitch' and is designed to lock the joining stitches in place.

The LS model creates an effective end-end seam for operations that require added security or for fabrics that will undergo a napping process.

The can be configured to produce a butted, gap, or overlap seam to achieve optimum results, according to the fabrics and manufacturing processes used.

WHY it's better

The traditional 16MM (5/8") Butt Seam stitch is ideal for joining fabrics, however in the case the stitch should not be removed (or cannot be compromised) the 70-D3B-2 LS should be used to Lock the Stitch (using two threads). The 70-D3B-2 LS was designed for processes that create significant and unpredictable tension on the seam.

HOW it's better

The 70-D3B-2 LS uses two threads and a new threading system to create the 16MM (5/8") Locked Stitch. The second thread tension and thread tube are accessible and allow the sewing head to deliver the same reliable performance at 2250RPM. We have modified the base model 70-D3B-2, reducing cost and creating efficiencies for companies that own other versions of the 70-D3B-2

WHERE it's used

The 70-D3B-2 LS has been designed for Napping and Shearing processes. It is also used in Billboard construction and hook and look manufacturing. The effectiveness of the locked stitch allows this 70 Class Machine to have broad appeal to markets outside of textile finishing (where the stitch is often removed) where joining materials with a PERMANENT FLAT SEAM is desirable.

| OPERATING SPEED | 2250 RPM |

| STITCH WIDTH | 16MM (5/8") |

| STITCH RANGE | 101MM - 305MM (4-12 SPI) |

| STANDARD NEEDLE | MERROW 8SDT |

| MERROW NEEDLE RANGE | MERROW 3SDT - 8SDT |

| FEDERAL STITCH TYPE | 501 |

| MOTOR REQUIRED* | 1725 RPM, 60 Hz, 1/2 HP, 110 or 220 volts, 1 or 3 phase |

| NUMBER OF THREADS | TWO THREAD |