72-D3B-2 Extended Feed Butt Seaming Machine

Merrow's butted seam machine designed for tubular knit material. The 72-D3B-2 is designed for handling difficult material and will accommodate anh knit or woven fabric.

The Advantage of the 72-D3B-2

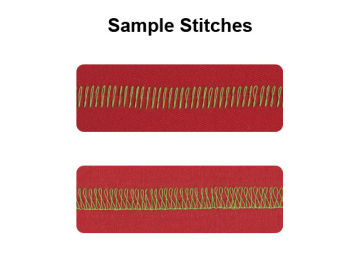

The Merrow 72-D3B-2 industrial sewing machine is designed to sew a consistent and flat butted seam on knit fabric. Specifically suited for tubular knits, the 72-D3B-2 can also be configured to sew a wide range of textiles.

Like all 72-Class Merrow machines, it incorporates an extended feed system and specially designed cutters that allow the consistent movement of sewn material across the cutting surface.

The 72-D3B-2 is hand assembled using high quality steel parts within the traditional Merrow cast iron frame, ensuring a perfect butted seam even after years of use.

WHY it's better

The 72-D3B-2 has been designed to improve on the 70-D3B-2 handling and cutting of fabrics. It represents an improvement on many mechanical areas of the 70-D3B-2 while still creating the same 16MM (5/8") stitch at 2250RPM. Significantly, the 72 Class machines will allow a 16MM (5/8") stitch on most knits.

HOW it's better

The 72-D3B-2 is significantly different from the 70-D3B-2.

- The Feed System is more robust, using three feed dogs instead of two.

- The Cutting System is entirely different and much more flexible. the 72-D3B-2 Cuts fabric 2" ahead of the 70-D3B-2

- The Pressure Foot is 90% Longer

- The Dust shield has been improved

- The Needle Plate is 60% larger and offers more room for fabric handling

WHERE it's used

The 72-D3B-2 is far better than the 70-D3B-2 sewing knits, and can be used in almost all operations where you would use the 70-D3B-2. These include:Continuous Bleaching, Mercerising, Scouring, Washing, Drying, Pad & Steam Dyeing, Printing, Steaming, Shrinking (Sanforizing), Finishing, Tubular Processing, Slitting & De-twisting, Heat Setting, Napping & Shearing, Singeing, Calendering. It will be mounted on a table and requires a 1/2HP motor or Merrow Air Motor.

| OPERATING SPEED | 2250 RPM |

| STITCH WIDTH | 16MM (5/8") |

| STITCH RANGE | 101MM - 305MM (4-12 SPI) |

| STANDARD NEEDLE | MERROW 8SDT |

| MERROW NEEDLE RANGE | MERROW 3SDT - 8SDT |

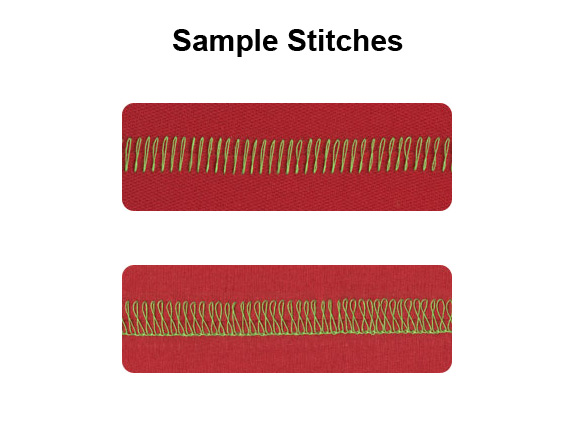

| FEDERAL STITCH TYPE | 501 |

| MOTOR REQUIRED* | 1725 RPM, 60 Hz, 1/2 HP, 110 or 220 volts, 1 or 3 phase |

| NUMBER OF THREADS | SINGLE THREAD |